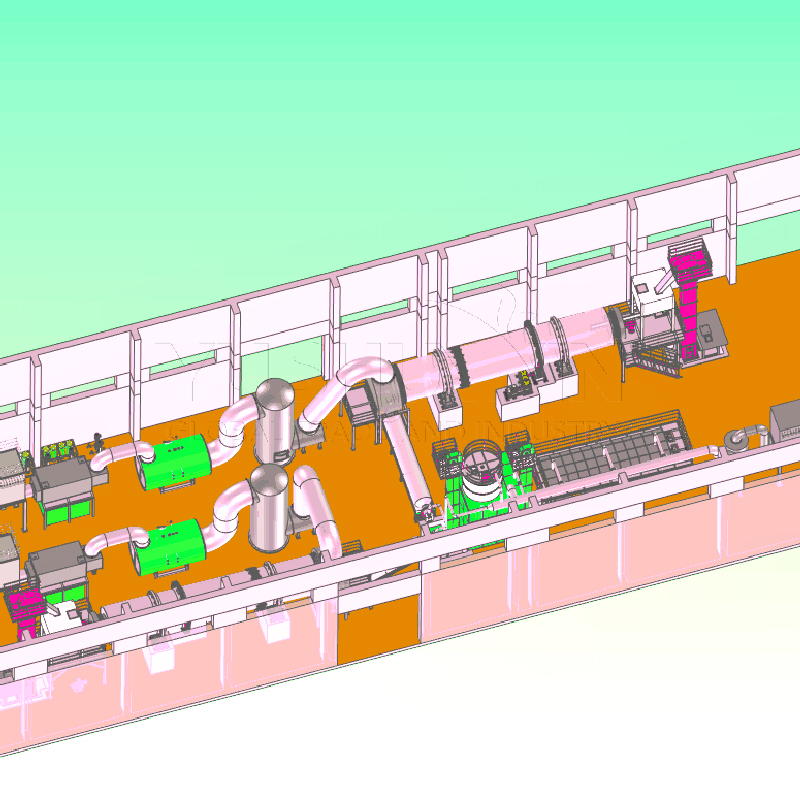

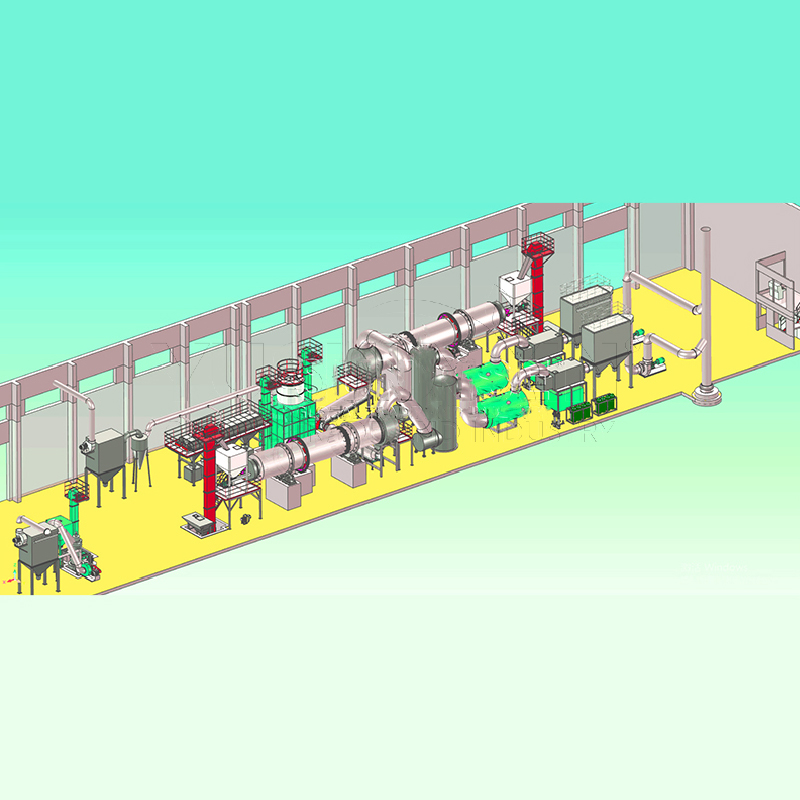

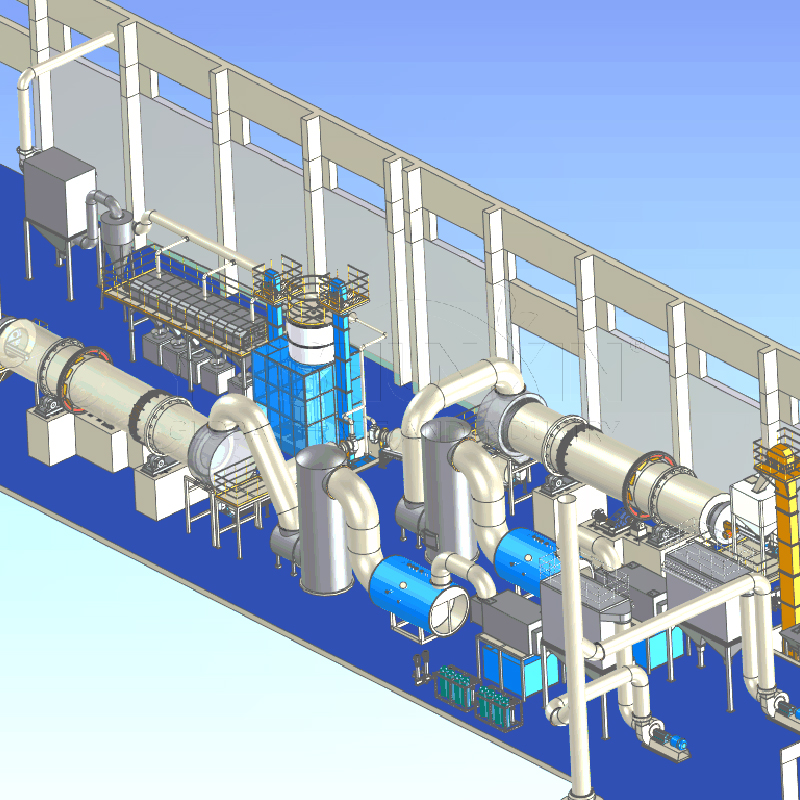

Activated carbon production line is one kind of continuous working line to transfer biomass to activated carbon in physical activated way. It fits for multiple biomass such as sawdust, Reisschale, coconut shell, palm kernel, bagasse, usw.

The production of activated carbon involves several key steps:

- Raw Material Selection: The first step is selecting the appropriate raw material.

- Preparation of Raw Material: The selected raw material is often prepared by drying and crushing it into small particles or granules.

- Carbonization: Carbonization is the process of heating the prepared raw material in the absence of oxygen, which is pyrolysis to convert it into charcoal.

- Activation: After carbonization, the charcoal is activated to create activated carbon.

- Sizing and Packaging: The final step involves sizing the activated carbon particles or granules to meet specific customer requirements.

- Quality Control: Rigorous quality control measures are essential throughout the production process to ensure that the activated carbon meets industry standards and customer specifications.

Working principle:

This physical way is to transfer biomass to charcoal firstly, and then are to be made apertures on biomass charcoal by using steam, which is for the purpose of getting more wide absorbing area.

- Continuous and large-scale production, high degree of automation, balanced temperature and good heat preservation effect.

- The main engine of the activation furnace adopts excellent processing and design, and has the characteristics of high temperature resistance and corrosion resistance.

- Simple operation and less labor force: using ordinary control cabinet or PLC control system, the degree of automation is high.

- The final product activated carbon has good indicators and can be widely used in water purification and other industries.

An activated carbon production line is a series of industrial processes and equipment used to manufacture activated carbon, which is a highly porous and adsorbent material. Activated carbon is utilized in various industries for purposes such as water purification, air and gas filtration, chemical processing, and more.