A biomass charcoal production line is a set of equipment used to convert biomass materials such as wood, straw, and plant waste into charcoal. It is an industrial manufacturing system used for large-scale production of carbonized products.

A typical continuous biomass charcoal production line may include the following key components:

- Raw Material Processing System: this section involves the preprocessing of raw materials, typically including crushing, drying or removal of impurities from particulate materials.

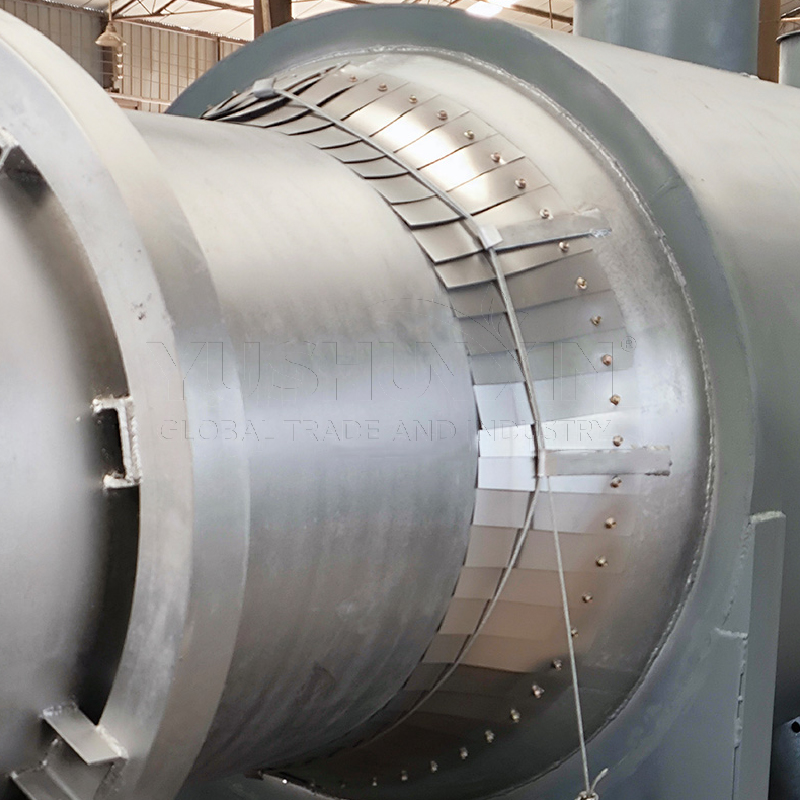

- Carbonizing Furnace: transfer dry raw materials into the preheated carbonizing furnace, which is the core component of the biomass charcoal production line. In the carbonizing furnace, the raw materials undergo pyrolysis at high temperatures, producing by-product gases and solid biomass charcoal.

- Cooling and Collection: the charcoal produced after carbonizing needs to be cooled and then can be collected and stored. At the same time, the collected gases can be recovered and utilized.

- Refining and Packaging: charcoal can undergo further refinement and processing to meet the requirements of various applications. The final biochar products can be packaged and sold.

- Control System: continuous biomass charcoal production lines utilize PLC control systems to monitor and adjust reaction conditions to ensure product quality and production efficiency.

- The applicable scope of raw materials is relatively wide. Raw wood, chaff, bamboo chips, nut shells, etc. can be used as raw materials for making charcoal.

- Made of special high-temperature resistant precious metal steel, which is strong and durable. It does not deform, oxidize, and has good thermal insulation performance.

- It is an automatic carbonizing machine equipment integrating incoming and outgoing materials, which improves the continuity and economy of the equipment.

- During the carbonizing process, it will have combustion gases such as carbon monoxide, methane, hydrogen, etc,which can be recycled, purified and circulated burning as heating source of the whole line machine.

- So that the whole set of equipment will not pollute the environment when working, but also provide its own heating use energy, which is a high efficiency equipment.

Wood charcoal machines can vary depending on the type and scale of carbonized products. They play a crucial role in sustainable resource utilization, environmental protection, and energy production because they can convert biomass materials into efficient energy and valuable by-products while reducing biomass waste and dependence on traditional energy resources.