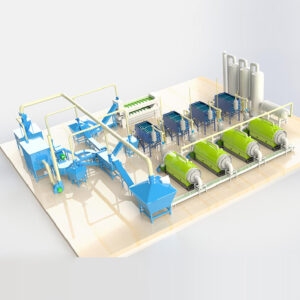

Il separatore di plastica in rame è una linea di produzione progettata per il riciclaggio di fili e cavi di rame. Schiaccia fili e cavi elettrici scartati per ottenere particelle di rame e particelle di plastica. La linea di produzione di riciclaggio del cavo presenta un design innovativo, struttura compatta, basso consumo energetico, e prestazioni stabili. Viene utilizzato principalmente per il riciclaggio di vari tipi di cavi scartati, Separare le materie prime in granuli di rame fini e PVC. È adatto per diametri a filo che vanno da 0,3 mm a 20 mm, compresi i fili automobilistici, fili di carreggiamento, fili motociclistici, fili di computer, e fili di cavi di comunicazione.

Questa apparecchiatura affronta i problemi associati al metodo di combustione per il recupero del rame. Non solo migliora la qualità del recupero del rame, ma consente anche il riciclaggio della plastica, Il che è buono per la protezione dell'ambiente.

- Struttura compatta, Aspetto esteticamente piacevole, disposizione razionale, e facile installazione.

- Il frantoio, attrezzatura di smistamento, e le attrezzature per la raccolta della polvere sono combinate su una piattaforma, Facilitare facile mobilità e trasporto, migliorando così la flessibilità delle attrezzature.

- Il rotore del frantoio adotta un design dell'albero della lama alternativa, Aumentare l'efficienza della produzione, Ridurre il rumore, e garantire un funzionamento stabile.

- La combinazione di macchina di smistamento dell'aria ad alta densità e dispositivo elettrostatico ad alta pressione raggiunge una velocità di smistamento di oltre 99%.

La macchina di separazione in plastica in rame viene utilizzata principalmente per il riciclaggio di vari fili sottili nell'intervallo di diametro da 0,3 mm a 20 mm. Ciò include cavi di comunicazione scartati, cavi del circuito automobilistico e motociclistico, elettrodomestico e cablaggio interno, cavi fili scartati, così come fili fini come il computer, telefono, e cavi di rete. È anche adatto per l'elaborazione di vari fili civili che non sono adatti per le macchine da stripping.