Echipamente de reciclare a deșeurilor electronice, cunoscut și sub denumirea de echipament electronic de mărunțire și sortare a deșeurilor, este folosit pentru reciclarea plăcilor de circuite din aparatele de uz casnic, cum ar fi televizoare și computere. După procesarea de reciclare, poate separa metalele și nemetalele pentru reutilizare ulterioară. Echipamentul de reciclare a deșeurilor electronice este potrivit pentru recuperarea diferitelor tipuri de plăci de circuite, placi PCB, placi FPCB, etc. Poate procesa direct plăci de circuite care conțin componente electronice, fără a fi nevoie de preprocesare. Metoda de separare în acest proces de reciclare a deșeurilor electronice este separarea uscată, eliminând nevoia de încălzire, combustie, spalarea cu apa, sau tratament chimic. Întregul proces de reciclare a deșeurilor electronice este fără poluare, făcându-l o soluție mecanică ecologică.

- Structură compactă, dispunere rațională, performanță stabilă, si zgomot redus.

- Utilizează controlul PLC pentru întreaga linie de producție pentru a asigura alimentarea uniformă și funcționarea coordonată.

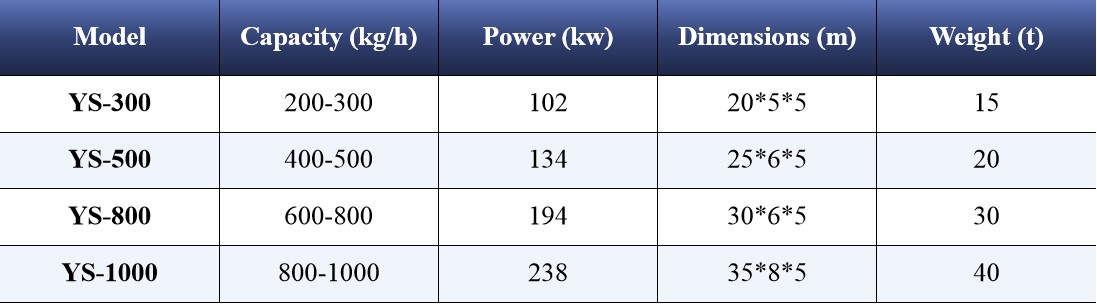

- Utilizează un proces de zdrobire în trei etape, realizarea unei capacităţi de procesare de 1000 kg pe oră.

- Camera de zdrobire încorporează un sistem de control al temperaturii apei în circulație pentru reducerea zgomotului.

- Întreaga linie de producție adoptă alimentare cu presiune negativă pentru a reduce în mod eficient debordarea prafului.

- Sistemul de reciclare sporește eficiența procesului de zdrobire.

- Echipamentul de sortare a fluxului de aer realizează o rată de sortare de peste 97%.

- Separatorul electrostatic de înaltă presiune asigură o sortare mai fină și mai eficientă, controlând eficient pierderile de metale neferoase.

- Echipat cu funcționalitate de separare magnetică pentru extragerea fierului din materiale.

Folosit pentru procesarea diferitelor plăci de circuite aruncate, precum plăcile de calculator, plăci pentru telefoane mobile, placi de televiziune, plăci placate cu cupru, și alte plăci de circuite de la aparatele de uz casnic, separând în cele din urmă metalele amestecate de nemetale.