产品详情

特征

范围 应用

E废物木炭生产厂是一套用于将电子废物转换为木炭的设备. 是用于大规模生产碳化产品的工业制造系统.

典型的生产工厂可能包括以下关键组件:

- 原料处理系统: 本部分涉及原材料的预处理, 通常包括粉碎和从颗粒物材料中去除杂质.

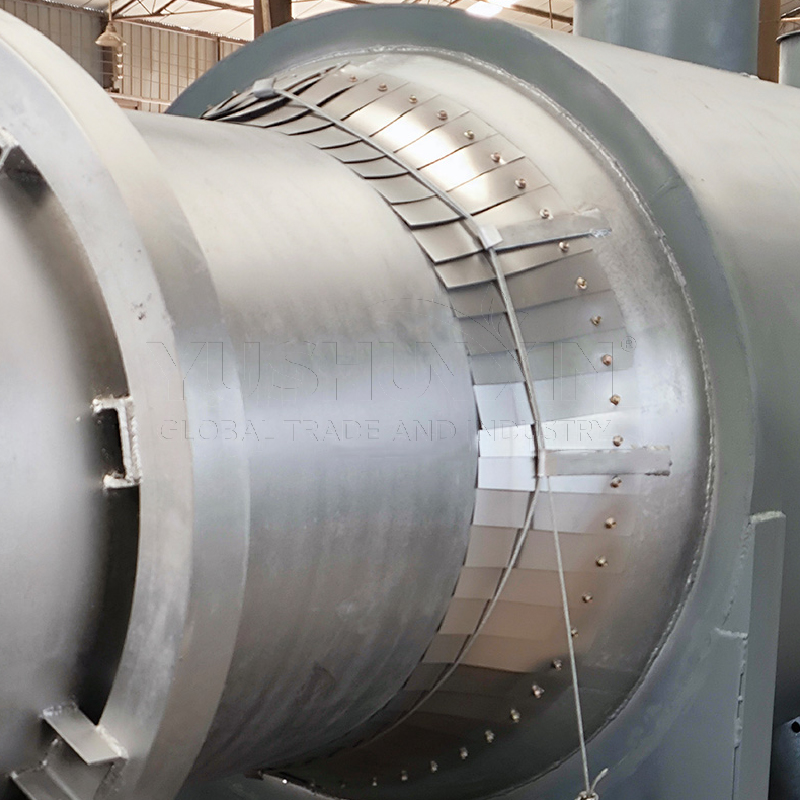

- 碳化炉: 将干燥的原料转移至预热的炭化炉内, 这是木炭生产线的核心组成部分. 在碳化炉中, 原料在高温下发生热解, 生产副产品气体和固体木炭.

- 冷却及收集: 炭化后产生的木炭需要冷却才能收集储存. 同时, 收集到的气体可以回收利用.

- 精炼和包装: 木炭可以进行进一步的精制和加工,以满足各种应用的要求. 最终的木炭产品可以包装和销售.

- 控制系统: 连续式生物质木炭生产线利用PLC控制系统监控和调节反应条件,确保产品质量和生产效率.

- 原材料适用范围比较广, 电子废物可以用作制造木炭的原材料.

- 采用特殊耐高温贵金属钢制成, 坚固耐用. 它不会变形, 氧化, 并具有良好的保温性能.

- 是一种进出料一体化的全自动炭化机设备, 改善设备的连续性.

- 碳化过程中, 会有一氧化碳等燃烧气体, 甲烷, 氢, ETC. 可以回收利用, 净化循环燃烧作为整线机的热源.

- 使整套设备工作时不会污染环境, 还能提供自己的供暖使用能源, 这是一种高效率的设备.

电子废物木炭生产工厂可能会根据碳化产品的类型和规模而有所不同. 它们在资源的可持续利用中发挥着至关重要的作用, 环境保护, 和能源生产,因为它们可以将浪费转化为有效的能源和有价值的副产品,同时减少浪费并依赖传统能源.