产品详情

特征

范围 应用

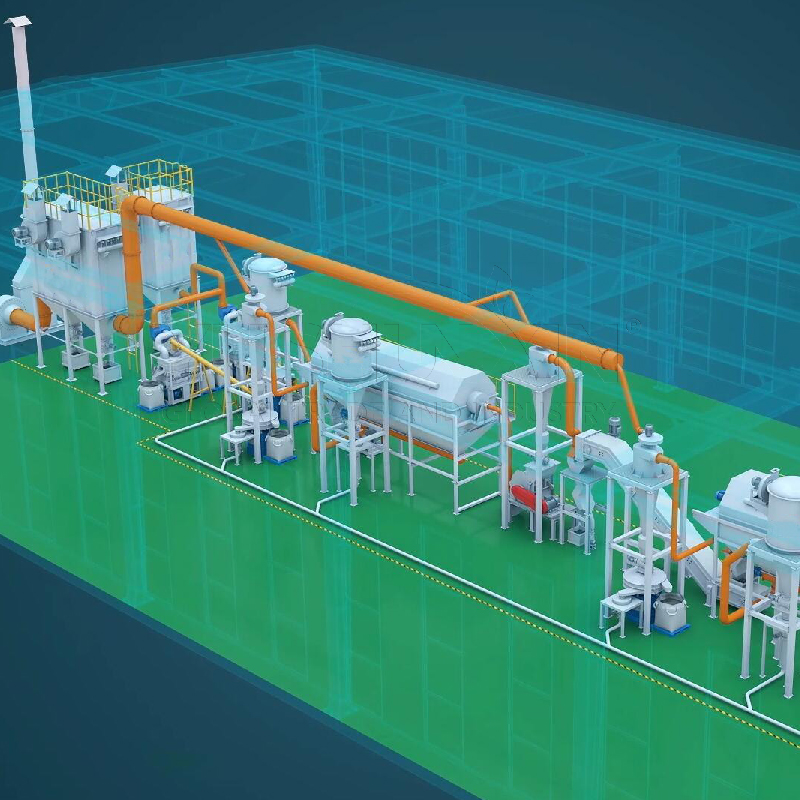

废旧锂电池回收设备专门针对废弃锂电池的处理和回收而设计. 这些设备通常涉及多个阶段的工艺,以确保从废旧锂电池中有效提取有价值的材料并进行后续处理以供再利用. 废旧锂电池回收设备首要目标是资源最大化回收, 特别是有价值的金属,如锂, 钴, 镍, 同时最大限度地减少对环境的影响.

废旧锂电池回收设备的使用有助于减少废旧电池对环境的负面影响,有利于有价值材料的有效回收, 促进资源可持续利用. 由于废旧锂电池中含有有毒有害物质, 适当的回收对于环境和人类健康至关重要.

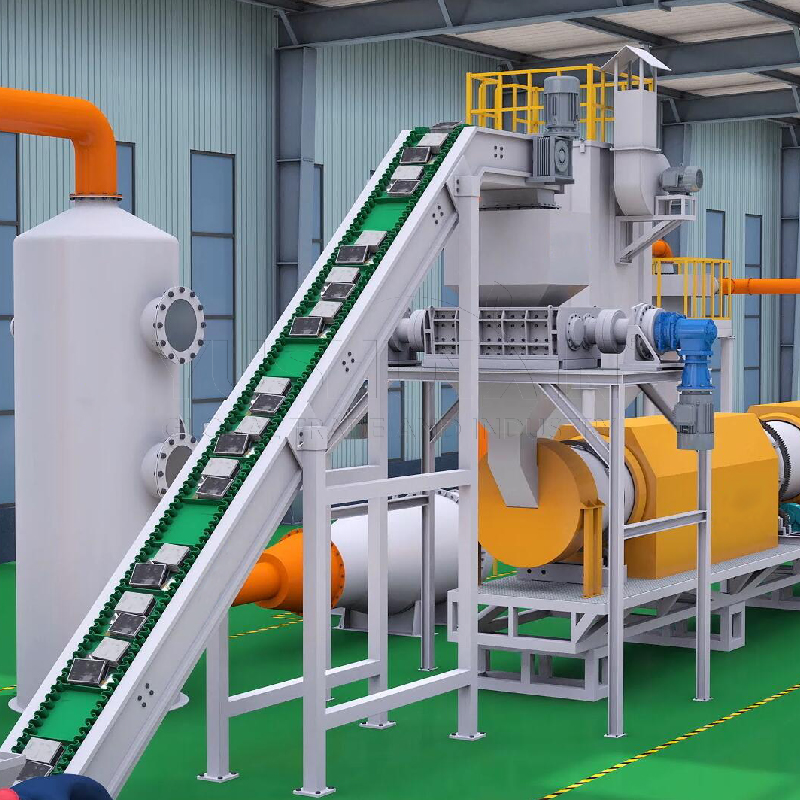

- PLC控制, 均匀喂料, 智能操作, 及自动报警功能使锂离子回收厂的操作更加方便, 节省时间, 且劳动效率高, 确保电池回收设施的最大稳定性.

- 磨床轴承采用水冷却系统, 显着提高轴承的使用寿命.

- 废电池粉碎机设备配备液压系统, 方便更换易损件,提高工作效率.

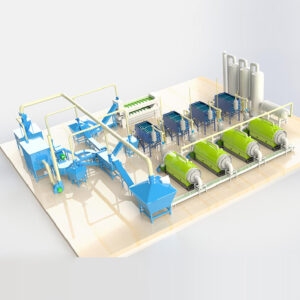

- 锂离子电池气流分选设备实现分选率高达 95%.

- 脉冲除尘器除尘率超过 99.99%, 确保无粉尘污染.

废旧锂电池回收研究主要集中在正极中的钴、锂等高价值贵金属. 锂电池回收生产线适用于软包电池拆解回收, 手机电池, 壳电池, 圆柱形电池, ETC. 最终产品主要包括石墨粉和铜.